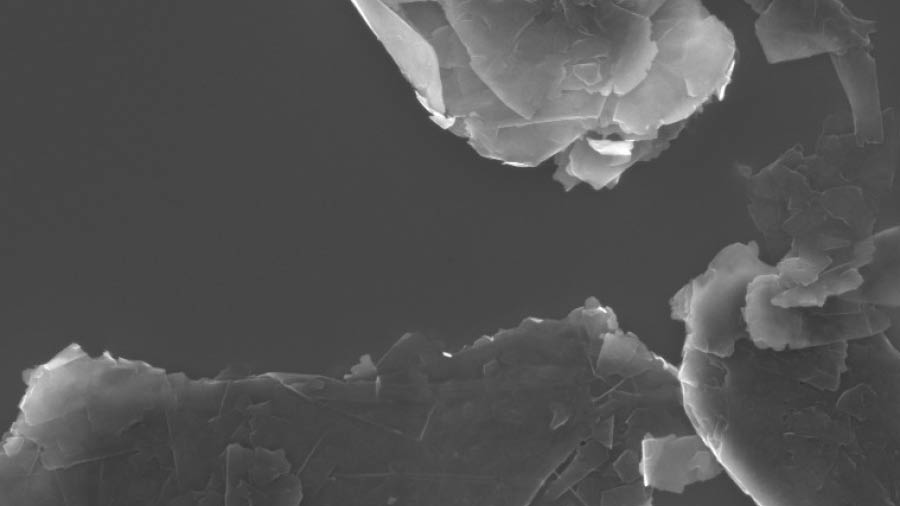

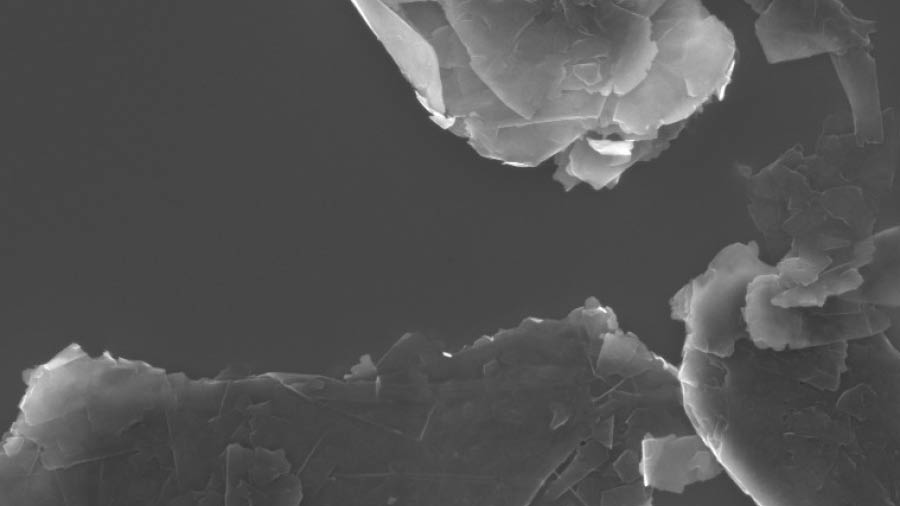

Graphene holds great promise across various applications, but to realize its full potential, scalable and reproducible production processes are essential. Graphene flakes, which constitute a significant portion of the market are commonly used as reinforcement material in composites, batteries, coatings, and filters.

In Sweden, graphene manufacturers are actively expanding production capacities, and there is a need for in-line characterization methods to monitor production processes and ensure quality control using cost-effective lab instruments. Our collaborative project focuses on addressing this need by leveraging automated optical microscopy and machine learning. Through these advanced technologies, we aim to precisely quantify the size and thickness distribution of exfoliated graphene flakes, offering a solution that enhances quality control for producers and improves the efficiency of volume production.

– In the pre-study we could see that it is possible to determine the thickness of graphene flakes by machine learning applied on light microscopy images. We are now further developing and fine-tuning this new, fast and cost-efficient characterization method, says Britta Andres, 2D fab.

The project encompasses various stages, including sample preparation, characterization, image processing, and deep learning method development. Ultimately, the code developed will be shared with industry partners, facilitating widespread adoption of this innovative approach.